- No Damage & No Moisture

- Non-Conductive–Safe on Electrical

- Non-Corrosive, Non-Toxic

- Sanitising

- No Secondary Waste

- No Down-time, Very Fast, Very Dry

years of

experience

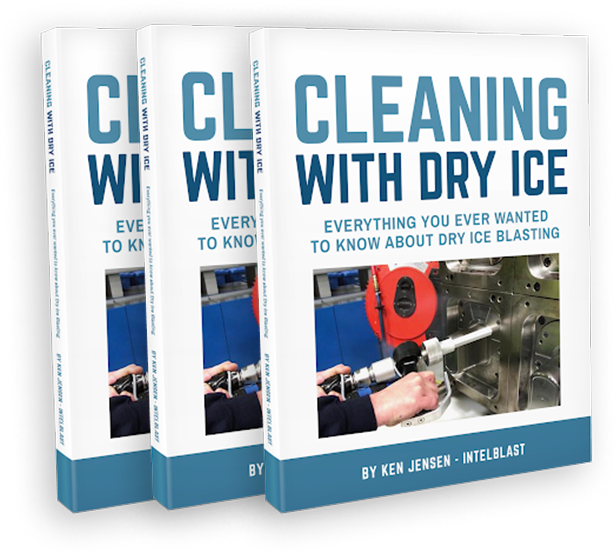

Dry Ice blasting is also known as, CO2 blasting, or cleaning with Dry Ice. Dry Ice is the solid form of carbon dioxide at-79 degrees C. For blasting the Dry Ice is accelerated in a pressurised air stream and expelled through the hose and nozzle. When directed at a surface, contamination is cleaned off without damaging the substrate. Dry Ice Blasting is similar to soda, and sandblasting but as it uses dry ice as the blasting medium, it is non-abrasive & leaves no secondary waste.

We sell and Service Intelblast Dry Ice Blasters & Equipment, we are authorised Intelblast Distributors for Australia & New Zealand.

We sell and Service Intelblast Dry Ice Blasters & Equipment, we are authorised Intelblast Distributors for Australia & New Zealand.  We sell dry Ice Production Equipment ( Pelletizers).

We sell dry Ice Production Equipment ( Pelletizers).  We produce our own Polar Dry Ice, always fresh & in quantities as required.

We produce our own Polar Dry Ice, always fresh & in quantities as required.  We hire out and sell compressors.

We hire out and sell compressors.  We do car underbody and component cleaning at our facility.

We do car underbody and component cleaning at our facility.  We c an supply Operators/Contractors to carry out complete cleaning operations at your site.

We c an supply Operators/Contractors to carry out complete cleaning operations at your site.  We supply full training in all aspects of Dry Ice Cleaning operations.

We supply full training in all aspects of Dry Ice Cleaning operations.  We also offer Soda Blasting & Dustless Blasting Services.

We also offer Soda Blasting & Dustless Blasting Services.

Dry Ice Blasting uses dry ice pellets (the same substance that carbonates drinks) for cleaning, producing no secondary waste like sand, water, or chemicals. It is an eco-friendly alternative to chemical and solvent-based methods.

This versatile process cleans heavy build-up without damage to sensitive areas like electrical components, switches, wiring, photo electric sensors, and more.

Since Dry Ice Pellets manage to reach every nook and corner of the equipment it cleans deeper and more effectively.

Dry Ice Blasting is completely dry, non-abrasive, non-toxic and non-corrosive. It quickly removes most contaminants without damage to switches, panels, lines, tubes, wiring or belts, HVAC equipment and is safe to use on electrical.